Page snapshot: Introduction to sugar from grasses, including types of sugar, sugar from sugarcane, sweet sorghum and sorghum syrup, corn syrup, and high fructose corn syrup.

Topics covered on this page: Introduction; What is sugar?; Sugar-producing crops; Sugar from sugarcane; Refined (white) sugar; Extraction of juice; Clarification and filtering; Evaporation (concentration); Crystallization, centrifugation, and drying; Refining; Cane syrup; Non-centrifugal sugar; Sweet sorghum and sorghum syrup; Corn syrup; High fructose corn syrup (HFCS); Resources.

Credits: Funded by the National Science Foundation. Any opinions, findings, and conclusions or recommendations expressed in this material are those of the author(s) and do not necessarily reflect the views of the National Science Foundation. Page by Elizabeth J. Hermsen (2023).

Updates: Page last updated February 16, 2023.

Image above: A broken sugarcane stalk resting on a bowl of refined sugar. Photo by Carl Davies (CSIRO Science Image, Creative Commons Attribution 3.0 Unported license, image cropped and resized).

Introduction

What is sugar?

Sugar is a type of carbohydrate. Carbohydrates are molecules produced by plants that contain carbon, hydrogen, and oxygen. Typically, these elements occur in a consistent ratio. Thus, the general formula for a carbohydrate is:

Cm(H2O)n

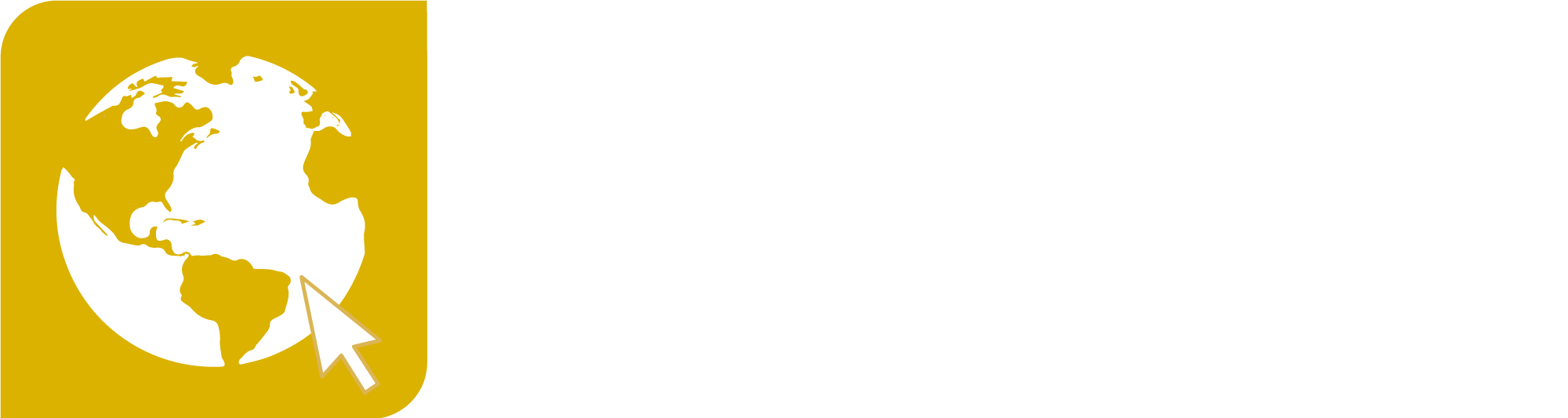

Carbohydrates are also called saccharides. They come in three forms. Simple carbohydrates or sugars are monosaccharides or disaccharides. That means that they are made up of one (mono-) or two (di-) saccharide units. The other types of carbohydrates are starches (complex carbohydrates) and fiber (cellulose, a substance that makes up the plant cell wall).

In colloquial or everyday usage, sugar typically refers to sucrose. Sucrose is the substance that makes up table sugar or white sugar. It is a disaccharide. Sucrose is made up of two monosaccharides bonded together, one unit of fructose and one unit of glucose.

A sucrose molecule. Photo by NEUROtiker (Wikimedia Commons, public domain).

Cane sugar or white sugar. Photo by Fritzs (Wikimedia Commons, Creative Commons Attribution-ShareAlike 3.0 Unported license, image resized).

Sugar-producing crops

Sugar typically comes from one of two crop plants: sugarcane (Saccharum officinarum and its hybrids), a tall grass that concentrates sugar in its stem, and sugar beet (Beta vulgaris), a plant in the amaranth family (Amaranthaceae) that concentrates sucrose in its root. Another grass, sorghum (Sorghum bicolor), comes in a sweet variety that is less frequently cultivated to produce sorghum syrup. Because all of these plants are high in sugar, they are also targets for production of biofuels, in which sugar is fermented to produce ethanol. So far, however, only sugarcane has been heavily exploited for this purpose, mostly in Brazil.

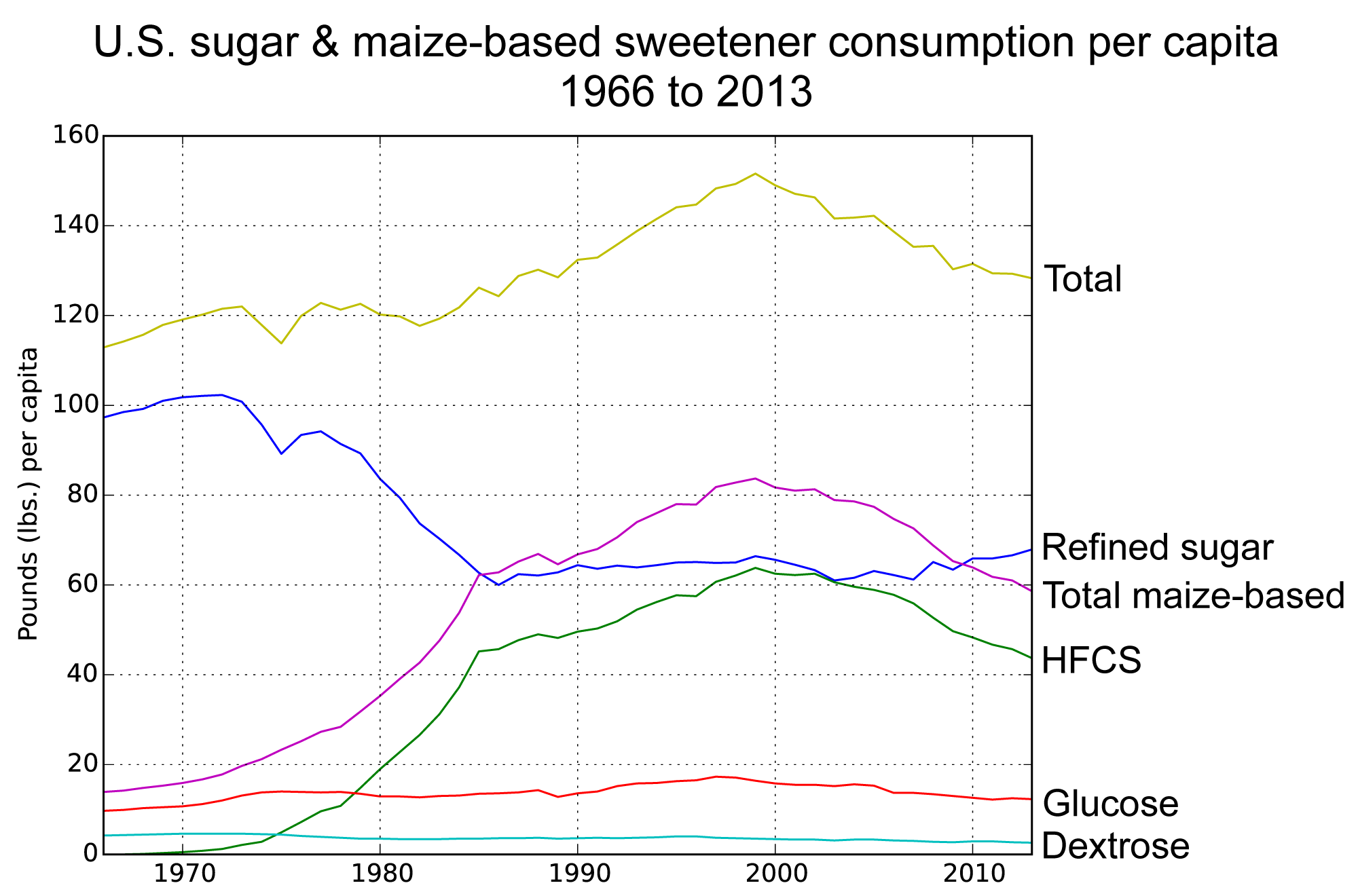

Today, many processed foods and artificially sweetened drinks (like sodas) are sweetened using corn syrup or high fructose corn syrup (HFCS) instead of or in addition to cane or beet sugar. Corn syrup is made by breaking down the starch in maize (Zea mays) kernels and consists of glucose and water. HFCS contains glucose, fructose, and water.

Bundles of sugarcane that have been harvested standing near a food stall. Photo by Thamizhpparithi Maari (Wikimedia Commons, Creative Commons Attribution-ShareAlike 3.0 Unported license, image cropped and resized).

Sugar beets growing in a field (left) and sugar beet roots following harvest (right). Left photo by 4028mdk09 and right photo by Stanzilla (Wikimedia Commons, Creative Commons Attribution-ShareAlike 3.0 Unported license, images cropped and left image resized).

Original caption: "Moses Siambi (ICRISAT) looks at sweet sorghum varieties being tested for biofuel production by Eco-Energia at Ocua, Mozambique." Photo by Swathi Sridharan, 2010 (flickr, Creative Commons Attribution-ShareAlike 2.0 Generic license, image resized).

Yellow dent corn in a field, Iowa, U.S.A. Photo by Don McCulley (Wikimedia Commons, Creative Commons Attribution-ShareAlike 4.0 International license, image cropped and resized).

Sugar from sugarcane

Sugarcane is a tall tropical grass in the genus Saccharum that is cultivated primarily as a source of sucrose. The juice in the sugarcane stem may be processed to produce refined sugar and/or other edible products. The juice or its derivatives like molasses can also be fermented to produce ethanol, which is used to make alcoholic beverages like rum and also ethanol biofuel.

Cultivation of sugarcane takes place primarily in the tropics, as sugarcane cannot survive winter freezes and needs a relatively long growing season to mature. Unlike grasses grown for grain, sugarcane is propagated asexually from whole stems or from pieces of stem called billets or setts. In regions where the climate allows, sugarcane can be grown as a perennial crop, meaning that it can be harvested and allowed to re-sprout to produce additional crops.

People planting billets in furrows, Sevangala, Sri Lanka, 2012. Photo by Ebaran (Wikimedia Commons, Creative Commons Attribution-ShareAlike 3.0 Unported license, image resized).

Refined (white) sugar

After harvesting, sugarcane must be processed into raw sugar, a precursor to refined sugar, quickly to prevent the sugary juices in the stalks from spoiling. Thus, at harvest time, sugar milling may go on 24 hours a day, 7 days a week.

Extraction of juice

After sugarcane is harvested and transported to the mill, it is typically shredded, then crushed and washed to extract the sucrose-containing juice. The fibrous plant material left over after sugarcane juice is extracted is called bagasse. Bagasse is often burned at the sugar mill to provide power or heat.

Truck and trailers full of harvested sugarcane, São Paulo, Brazil. Photo by Edrossini (Wikimedia Commons, public domain).

Rotary tipler, a machine that tips trailer-loads of sugarcane to unload them at the sugar mill. Queensland, Australia, 1980. Photo by srv007 (flickr, Creative Commons Attribution-NonCommercial 2.0 Generic license, image cropped and resized).

A modern machine for crushing sugarcane to extract juice. Notice the grooved rollers used to crush the cane. Photo by Sourabhpredekar (Wikimedia Commons, Creative Commons Attribution-ShareAlike 4.0 International license, image cropped).

Pile of bagasse, Phetchabun, Thailand. Photo by KusiD (Wikimedia Commons, Creative Commons Attribution-ShareAlike 4.0 International license, image cropped).

Clarification and filtering

After the juice is extracted, it is clarified (meaning, impurities are removed) and filtered. During clarification, chemicals are added to the diluted sugarcane juice; these chemicals react with impurities in the juice to form solids. The treated juice sits in a settling tank, where the solids are allowed to settle out, accumulating at the bottom of the tank as a substance called mud.

The slurry of mud and some of the sugarcane juice from the bottom of the tank is collected and moved to a rotary filter, which filters out the mud. The solid mud can be recycled as a fertilizer or used for other industrial or agricultural purposes. The juice from the slurry is captured and mixed back in with unclarified sugarcane juice to go through the clarification process again. The rest of the juice, called clarified juice, moves on to the next step in processing.

Rotary filters used to filter mud from sugarcane juice after clarification, Kekaha Sugar Company, Hawai'i. Photo by David Franzen (Library of Congress, Reproduction Number HAER HI-83-39, no known restrictions).

Evaporation (concentration)

The clarified juice is next heated so that the some of the water in it evaporates, concentrating the liquid and thus raising its sucrose content. The concentrated liquid is now called syrup. Modern sugar mills use vacuum evaporators to concentrate the juice. Heating the sugary juice under vacuum means that the liquid will boil at a lower temperature than it would in an open container.

Crystallization, centrifugation, and drying

The concentrated syrup is transferred to a vacuum pan. Sugar crystals are added to the heated syrup to spur the sucrose to crystallize, producing a thick liquid called massecuite. The massecuite is moved to centrifugals that spin, separating the solid sugar crystals from the liquid in the massecuite. The liquid, called molasses, is another product of sugar; it is used as food, to make rum, or produce livestock feed. The crystals are dried to make raw sugar.

Raw sugar produced at the sugar mill may be non-food-grade, meaning that it is not considered suitable for human consumption. The raw sugar is shipped to a refinery before it is processed further.

Vacuum pans and centrifugals in a sugar factory on the island of Réunion. Photo by David Monniaux (Wikimedia Commons, Creative Commons Attribution-ShareAlike 3.0 Unported license).

A continuous vacuum pan, Hawaiian Commercial & Sugar Company Mill, Maui, Hawai'i. Photo by Fives Fletcher - Fives Cail -Fives Fletcher (Wikimedia Commons, Creative Commons Attribution-ShareAlike 3.0 Unported license).

Molasses. Left photo by Chris Waits (flickr, Creative Commons Attribution 2.0 Generic license, image cropped and resized); right photo by Badagnani (Wikimedia Commons, Creative Commons Attribution 3.0 Unported license, image cropped and resized).

Raw sugar at the Redpath Sugar Refinery, Toronto, Canada, 2010. Photo by Loozrboy (flickr, Creative Commons Attribution-ShareAlike 2.0 Generic license, image cropped and resized).

Refining

Once at the refinery, the raw sugar is melted (mixed with liquid) and passed through a series of steps to refine it: clarification, filtration, and decolorization. Afterwards, the melted sugar is heated again under vacuum to remove the liquid. The sugar is crystallized and then centrifuged again to remove the remaining molasses. If white sugar is being produced, the sugar can then be dried, packaged, and distributed. Modern, commercially produced brown sugar is typically made from refined white sugar with molasses added back. Powdered sugar or confectioner's sugar is made of finely ground sugar mixed with a little cornstarch.

The Domino Sugar refinery in Baltimore, Maryland, U.S.A. Photo by Acroterion (Wikimedia Commons, Creative Commons Attribution-ShareAlike 4.0 International license, image resized).

Powdered sugar or confectioner's sugar. Photo by Teresa Trimm (flickr, Creative Commons Attribution-ShareAlike 2.0 Generic license).

Cane syrup

Cane syrup is produced by extracting the juice from sugarcane, straining it, then heating it so that it that it thickens into syrup. Cane syrup should not be confused with simple syrup (made by heating a mixture of sugar and water) or invert syrup (made by adding an acid to a sugar and water solution to break down the sucrose into fructose and glucose molecules). Cane syrup is a traditional product of the southeastern U.S.

Grinding sugarcane to make syrup, Florida, U.S.A. Left photo by John Marshall (1981), right photo by Nancy Nusz (1990) (Images FS821129 and FA4211, Florida Memory/State Library and Archives of Florida, public domain).

Boiling sugarcane juice to make syrup (left) and bottling syrup (right), Florida, U.S.A., 1980s. Photos by Andrea Graham (left) and Merri Belland (right) (Images FA4167 and FA4095, Florida Memory/State Library and Archives of Florida, public domain).

Non-centrifugal sugar

Non-centrifugal sugar is a traditional solid sugarcane product with a brown color. It goes by various regional names, including kokuta in Japan, gur in India, jaggery in Africa and parts of Asia, and panela, piloncillo, or rapadura (among other names) in Latin America. Non-centrifugal sugar is made by heating and evaporating the juice squeezed from the sugarcane stalk, leaving a thick syrup. This syrup is cooled in a mold, yielding a solid sugar product.

The main difference between non-centrifugal and refined sugar is that in refined sugar, molasses is separated from the sugar syrup and the sugar is processed to produce uniform white crystals that are visible to the naked eye. While non-centrifugal sugar contains a large amount of sucrose, it is made up of very small, irregular crystals. Non-centrifugal sugar also contains other natural compounds.

Jaggery cubes. Photo by Mangosapiens (Wikimedia Commons, Creative Commons Attribution-ShareAlike 4.0 International license, image cropped and resized).

A man producing jaggery from sugarcane, Karnataka, India. In the photo, a sugarcane grinder can be seed in the background, next to a pile of bagasse (crushed sugarcane stalks). In the foreground, a man is stirring a kettle of cane syrup. Photo by Jedesto (Wikimedia Commons, Creative Commons Attribution-ShareAlike 4.0 International license, image cropped and resized).

Producing jaggery from sugarcane, Punjab, Pakistan. In the photo, a kettle of sugarcane syrup can be seen in the background and jaggery can be seen on the tarp in the foreground. Photo by Khalid Mahmood (Wikimedia Commons, Creative Commons Attribution-ShareAlike 3.0 Unported license, image resized).

Sweet sorghum & sorghum syrup

Sweet sorghum is a type of domesticated sorghum (Sorghum bicolor subspecies bicolor) that accumulates sucrose in its stem. Sorghum is thought to have been domesticated in tropical Africa. Nevertheless, it can be grown as an annual crop in temperate regions. In other words, while sorghum has to be replanted every year, it can grow to maturity in one growing season in temperate regions. In regions that do not experience freezing, it can be grown as a perennial crop. Thus, sorghum stands in contrast to sugarcane, which can only be grown in tropical to subtropical regions with extended growing seasons and mild winters. Sorghum is grown from seed.

Original caption: "Paul Cochran, a farmer from Portland, cuts slices of sweet sorghum stalk to taste for sweetness. Drs. Nilda Burgos and Leopoldo Estorninos and Jerry Gregory, a certified crop consultant from Lake Village, look on during a field day at the University of Arknasas Division of Agriculture's Rohwer Research Station." Photo source: AAES Director on flickr (Creative Commons Attribution-ShareAlike 2.0 Generic license, image resized).

Because of its high sucrose content, ability to be grown in temperate zones, and drought tolerance, sweet sorghum is seen as a potentially attractive plant for producing biofuels. Nevertheless, it is currently not widely grown for this purpose, as maize and sugarcane are the primary biofuel crops.

Sweet sorghum is grown in tropical to subtropical regions for use as human food, livestock fodder, and a source of sugary juice for making sorghum syrup, non-centrifugal sugar, and sorghum beer. Sweet sorghum is traditionally used to make sorghum syrup (sometimes incorrectly called sorghum molasses) in a process similar to that used to make sugarcane syrup in the United States.

Stalks of sweet sorghum that will be used to make sorghum syrup, Nebraska, U.S.A., 1938. Photo by John Vachon (Farm Security Administration, Office of War Information Photograph Collection, Library of Congress Reproduction Number LC-DIG-fsa-8a03610, no known restrictions).

A man grinding sorghum stalks to extract the sugary juice, North Carolina, U.S.A., 1935. Photo by Arthur Rothstein (Farm Security Administration, Office of War Information Photograph Collection, Library of Congress Reproduction Number LC-DIG-fsa-8a07472, no known restrictions).

Women skimming hot sorghum juice, North Carolina, U.S.A., 1939. Photo by Marion Post Wolcott (Farm Security Administration, Office of War Information Photograph Collection, Library of Congress Reproduction Number LC-DIG-fsa-8a40825, no known restrictions).

Corn syrup

Corn syrup and high fructose corn syrup (HFCS) are made mostly from kernels of yellow dent corn, which is a type of corn that has dented kernels. Maize was domesticated in southern Mexico, but it is widely grown as a crop in the temperate zone, since it can complete its life cycle in the shorter temperate growing season.

Ears of yellow dent corn. Photo by Jonathunder (Wikimedia Commons, Creative Commons Attribution-ShareAlike 3.0 Unported license, image cropped and resized).

Unlike sugar and sorghum, maize does not accumulate high concentrations of sucrose in its stem. Rather, like other grains, maize accumulates starch in its kernels. Starch molecules are complex, so they must be broken down in order to yield sugar molecules. Sugar made from maize kernel starch is used to produce corn syrup for human consumption. Sugar from maize kernel starch may also be fermented to produce ethanol, which is used to make ethanol biofuel or alcoholic beverages, like bourbon.

Production of corn syrup starts with whole maize kernels. The first step is to isolate the starch from the kernels in a process called wet milling. Wet milling involves soaking the kernels in a large vat of slightly acidic hot water. The soaked kernels are then ground into a slurry, which is spun to separate the germ (oil-containing embryos) from the other components of the kernels. The remainder of the mixture is ground again, then filtered to remove the fiber. Finally, the mixture is spun and thoroughly washed to remove the protein, leaving nearly pure cornstarch.

Starch in maize kernels consists of long chains of glucose molecules that must be broken apart. In order to do this, two enzymes are added to the cornstarch, one after the other. The first breaks the starch into simpler carbohydrates, and the second breaks the simpler carbohydrates into glucose molecules, yielding corn syrup.

Tank care carrying corn syrup, Illinois, U.S.A. Photo by Larry Darling (flickr, Creative Commons Attribution-NonCommercial 2.0 Generic license, image cropped and resized).

High fructose corn syrup (HFCS)

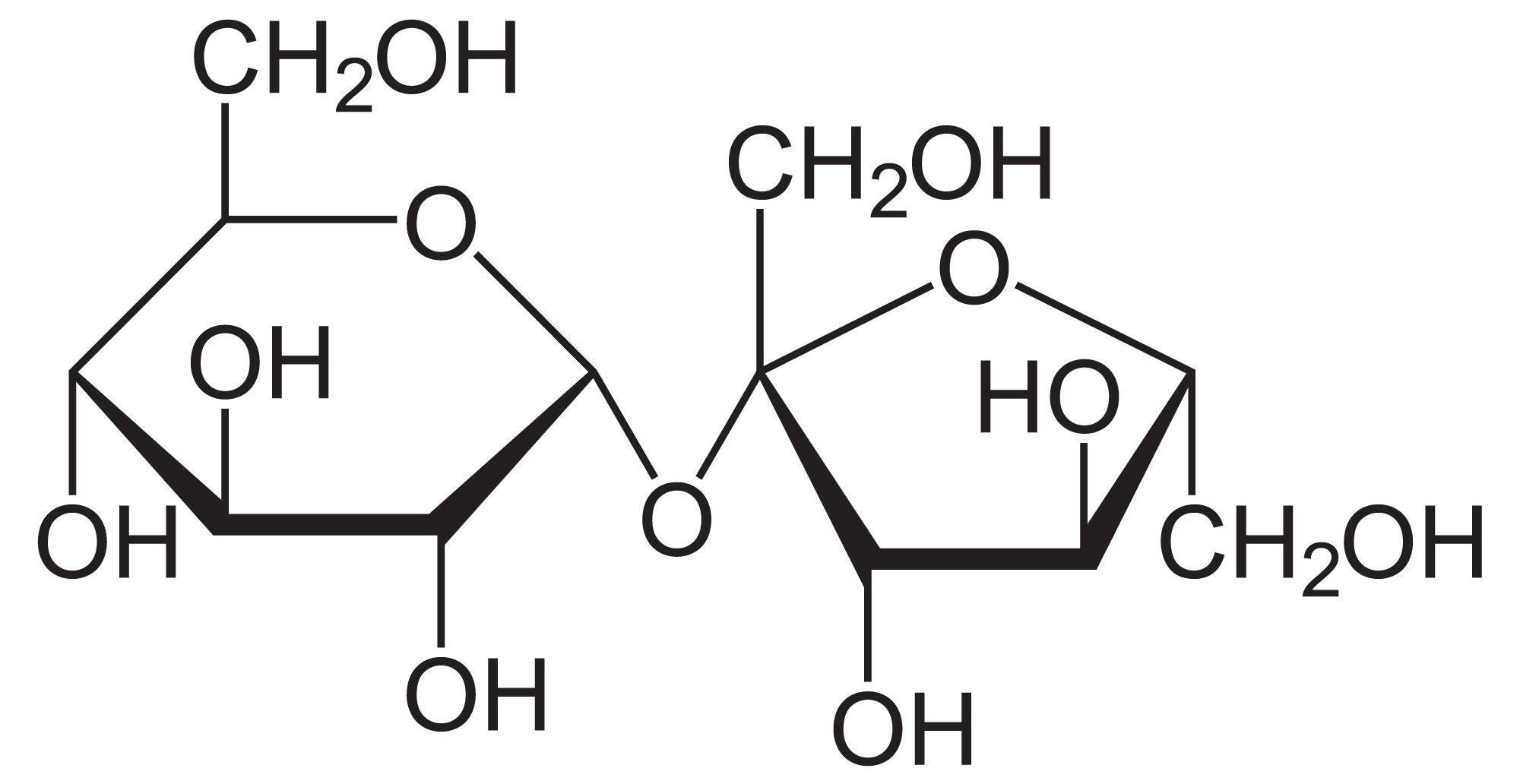

Today, many processed foods and sweetened beverages use high fructose corn syrup rather than cane or beet sugar. HFCS is made by treating corn syrup with a third enzyme that converts glucose molecules into fructose molecules, which are sweeter in flavor. There are several types of HFCS, which are differentiated by the percent fructose sugar they contain. The two most common used in food and drinks are HFCS 42 (42% fructose) and HFCS 55 (55% fructose).

HFCS has advantages over sucrose for food and drink manufacturers. HFCS is cheaper than sucrose. It is liquid, so it is a convenient sweetener for use in beverage production. It is also more stable than sucrose in certain processed foods and has preservative qualities, helping to keep food from spoiling.

Nutrient label for strawberry jam with three types of sweeteners: HFCS, corn syrup, and sugar. Photo by Food Thinkers (flickr, Creative Commons Attribution-NonCommercial-ShareAlike 2.0 Generic license, image cropped).

Some have criticized the widespread use of HFCS in food and drink products. Some consumers dislike the flavor of HFCS. Health advocates argue that widespread use of HFCS is linked to poor health. While HFCS is sometimes singled out for contributing to conditions like fatty liver disease, diabetes, and cardiovascular disease, there is currently no evidence that HFCS is worse for health than sucrose. Rather, high sugar consumption in processed foods and sweetened drinks regardless of the form or source of sugar has probably contributed to the rise in certain health problems in the U.S. population and worldwide.

Resources

Websites

High fructose corn syrup questions and answers (FDA): https://www.fda.gov/food/food-additives-petitions/high-fructose-corn-syrup-questions-and-answers

Sugar and sweeteners (USDA Economic Research Service): https://www.ers.usda.gov/topics/crops/sugar-and-sweeteners/

Sugar glossary (USDA Farm Service Agency): https://www.fsa.usda.gov/programs-and-services/economic-and-policy-analysis/dairy-and-sweeteners-analysis/sugar-glossary/index

Sweet sorghum research (I. Dweikat, University of Nebraska-Lincoln Department of Agronomy and Horticulture): https://agronomy.unl.edu/sweetsorghum

Videos

A sweet tradition - Jasper County cane syrup: Mississippi Roads (Mississippi Public Broadcasting): https://youtu.be/V93RXotMtGc

CSEC Chemistry: Extracting sucrose form sugarcane (Caribbean Toots): https://youtu.be/kGNxBbLpiEk

How sugar is made (How It's Made, Discovery UK): https://youtu.be/wvuiavj0pIo

Making cane syrup the old way (The Homestead Box): https://youtu.be/PrSvzBF5l0I

Making raw sugar (Wilmar Sugar Australia): https://youtu.be/6GRl316hYPI

Making refined sugar (Wilmar Sugar Australia): https://youtu.be/xC5-ABckO-c

Articles & reports

Caldwell, J. 2022. Fructose is fructose is fructose (American Council on Science and Health): https://www.acsh.org/news/2022/04/27/fructose-fructose-fructose-16280

Corn Refiners Association. The corn refining process. PDF: https://corn.org/wp-content/uploads/2009/11/CornRefiningProcess.pdf

Farm Energy. 2019. Sweet sorghum for biofuel production. April 3, 2019. https://farm-energy.extension.org/sweet-sorghum-for-biofuel-production/

Mackintosh, D. 2000. Sugar milling. Pp. 369-377 in M. Hogarth and P. Allsopp, eds. Manual of Canegrowing. Bureau of Sugar Experiment Stations, Fergies Printers, Brisbane. https://elibrary.sugarresearch.com.au/bitstream/handle/11079/15541/Chapter%2017%20Sugar%20Milling.pdf

McHugh, T. 2020. How sugar is processed. Food Technology Magazine, July 1, 2020. https://www.ift.org/news-and-publications/food-technology-magazine/issues/2020/july/columns/processing-how-sugar-is-processed

Rajvanshi, A. K. 2018. From food to fodder, here's how this magic plant can take care of our needs. The Better India, December 20, 2018. https://www.thebetterindia.com/167321/sugar-replacement-eco-friendly-ethanol-production-india/

Singh, J., S. Solomon, and D. Kumar. 2013. Manufacturing jaggery, a product of sugarcane, as health food. Agrotechnology, S11, 3 pgs. https://doi.org/10.4172/2168-9881.S11-007

Tran, G. 2015. Sugarcane press mud. Feedipedia, last updated May 27, 2015. https://www.feedipedia.org/node/563

Books

Levetin, P., and D. S. McMahon. 2016. Plants and Society, 7th ed. McGraw Hill Education, New York.

Simpson, B. B., and M. C. Ogorzaly. 2001. Economic botany, plants in our world, 3rd ed. McGraw Hill Higher Education, New York, New York.

Scientific articles

Parker, K., M. Salas, and V. C. Nwosu. 2010. High fructose corn syrup: Production, uses and public health concerns. Biotechnology and Molecular Biology Review 5: 71-78.