Page snapshot: Introduction to biofuels from grasses, including bioethanol, cellulosic ethanol, biodiesel, and biogas and biomethane.

Topics covered on this page: Introduction; Bioethanol from sugars; Production of ethanol from plants; Bioethanol from maize; Bioethanol from sugarcane; Use of bioethanol fuels; Cellulosic ethanol; Biodiesel; Biogas and biomethane; Resources.

Credits: Funded by the National Science Foundation. Any opinions, findings, and conclusions or recommendations expressed in this material are those of the author(s) and do not necessarily reflect the views of the National Science Foundation. This page incorporates content prepared for the Teacher-Friendly Guide to the Evolution Maize (T. M. Fulton, C. S. Buckler, and R. A. Kissel, 2011). Additional content and revisions by Elizabeth J. Hermsen (2023).

Updates: Page last updated February 27, 2023.

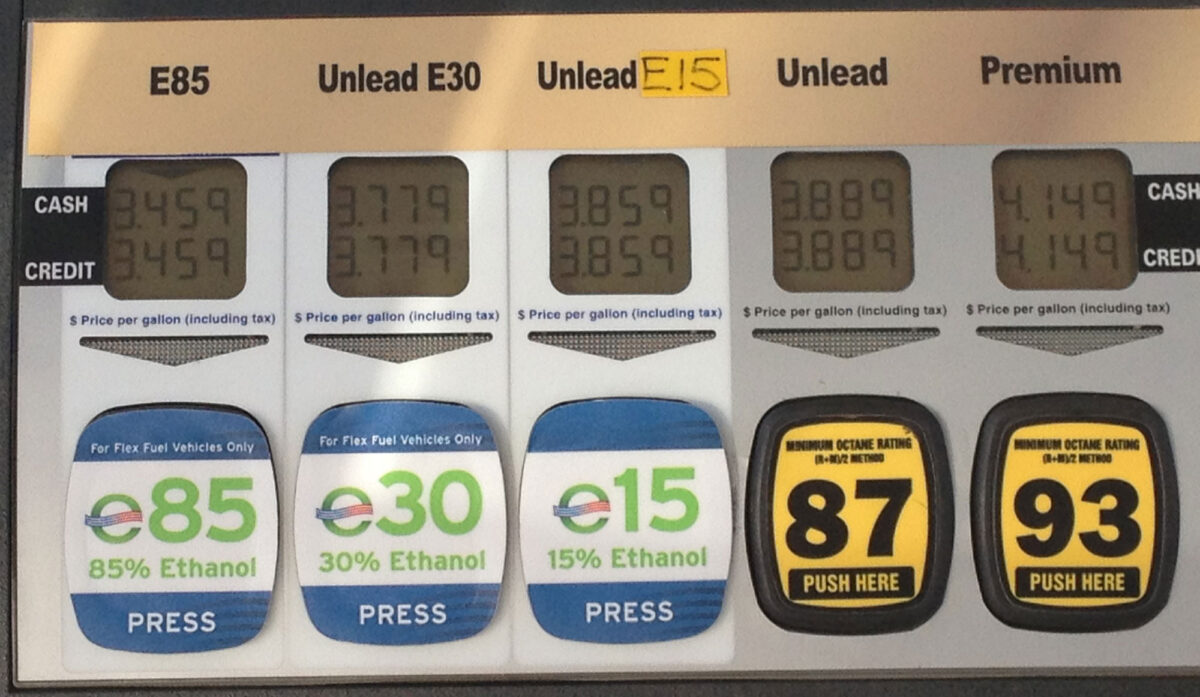

Image above: A fuel pump that dispenses different ethanol-containing fuel blends and fossil fuels. Photo by 127driver (Wikimedia Commons, CC0 1.0 Universal Public Domain Dedication).

Introduction

A biofuel is any fuel that is derived from a living or recently living organism, or organic matter produced by a recently living organism. Biofuels can be contrasted to fossil fuels, which are produced from the organic remains of long-dead organisms. Biofuels have many uses, including to power vehicles and to heat homes. Interest in biofuels is increasing because biofuels, unlike fossil fuels, are a renewable resource and arguably better for the environment.

Grasses are primarily used to produce biofuel for transportation in the form of bioethanol, a type of alcohol that comes from biological sources. Biofuel production requires cultivating the crop and transporting materials to a processing plant. Thus, biofuel production has costs and, at least currently, requires burning some fossil fuels in the form of gasoline for farm equipment, transportation, and electricity to run processing plants.

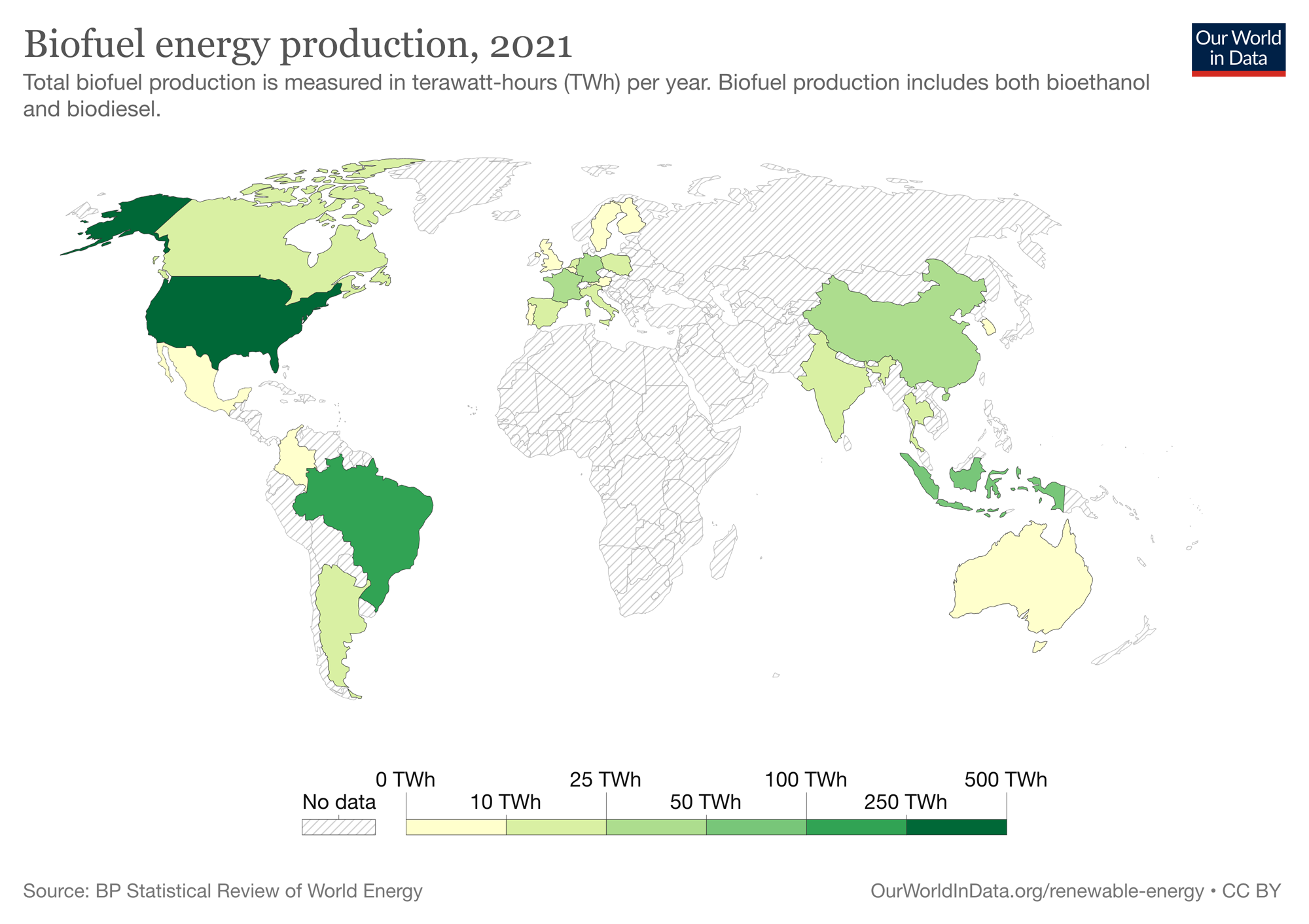

World map of biofuel energy production in 2021 by country. This map includes only bioethanol and biodiesel production. Map from Our World in Data (Creative Commons Attribution 4.0 International license, image resized).

Flexfuel SUV that can run on E85, or 85% ethanol fuel. Photo by Daniel Schwen (Wikimedia Commons, Creative Commons Attribution-ShareAlike 4.0 International license, image cropped and resized).

Bioethanol from sugars

Plant sugars can be fermented to produce ethanol (ethyl alcohol) that can be used as fuel or mixed with fossil fuels to produce a blend. Plants most often used for bioethanol production are maize (Zea mays subsp. mays) and sugarcane (various Saccharum species), although other types of plants with high starch or sugar concentrations are being considered for commercial production. Sweet sorghum (Sorghum bicolor), for example, is another type of grass that may be a source of sugar to make economically viable ethanol, although it has not been widely exploited so far for this purpose.

Maize kernels. Photo by Danielgrad (Wikimedia Commons, Creative Commons Attribution-ShareAlike 3.0 Unported license, image resized).

Sugarcane field, Queensland, Australia. Photo by Willem van Aken (Wikimedia Commons, Creative Commons Attribution-ShareAlike 3.0 Unported license, image resized).

Production of ethanol from plants

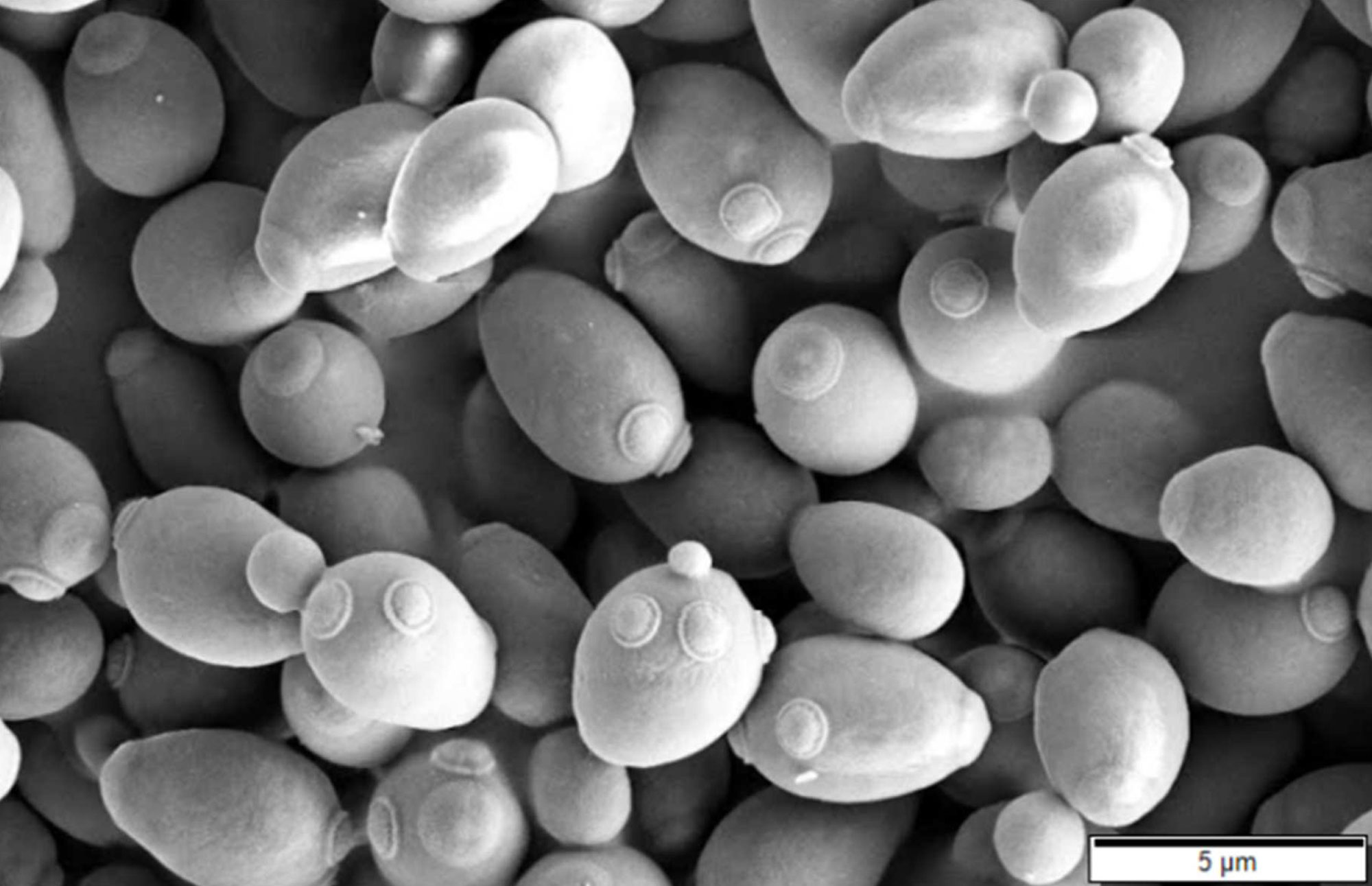

Sugar from plants must be fermented to produce ethanol. Fermentation is an anaerobic process, or a process that takes place in the absence of oxygen (O2). During fermentation, yeast (a single-celled fungus), converts sugar into ethanol and carbon dioxide gas (CO2). Fermentation by yeast is also the process used to make alcoholic beverages, which also contain ethanol. A formula for this process is:

C6H12O6 → 2C2H5OH + 2CO2

The liquid produced by fermentation, called beer in the bioethanol production process, is relatively low in ethanol. In order to increase its ethanol content, the low-ethanol beer is distilled. Distillation is a process used to separate liquids, in this case water and alcohol. During distillation, the beer is heated to a temperature high enough to make ethanol boil, but low enough that water does not boil. The ethanol vapor is captured and condensed (cooled so that it returns to a liquid state), yielding a liquid that is more than 90% ethanol. The high-ethanol liquid is then strained through molecular sieves to remove the remaining water until the ethanol is nearly pure.

A scanning electron micrograph of yeast (Saccharomyces cerevisiae). Yeast are single-celled fungi that reproduce by budding, and buds can be seen forming on the yeast above. Photo by Mogana Das Muret adn Patchamuthu Ramasamy (Wikimedia Commons, Creative Commons Attribution-ShareAlike 3.0 Unported license, image resized).

Bioethanol from maize

In the United States, maize kernel starch is typically the source of sugar used to produce ethanol. In order to make ethanol from maize, the kernels must first be processed. Typically, the kernels are milled, meaning that they are ground and the starch is separated from the other components of the kernel (fiber, oil, and protein). The starch is then mixed with water, and enzymes are added to break the complex starch molecules into simple glucose (sugar) molecules that the yeast can process during fermentation.

Maize oil separated during the milling process is diverted for various uses, such as making biodiesel (read more below) or poultry feed. The leftover solid kernel waste from maize ethanol production, called stillage or distillers grains, is used for animal feed. Distillers grains may be used wet or dried. Drying allows the distillers grain to be stored for a longer period of time and transported further, but requires more energy than producing wet grain.

A bioethanol plant, West Burlington, Iowa. Photo by Steven Vaughn (Wikimedia Commons, Agricultural Research Service/public domain).

Original caption: "A truck picks up a load of distillers grain byproduct from the ethanol plant. It’s not taken very far, just across the road and fed to the cattle." Photo by David Dodge, Green Energy Futures (flickr, Creative Commons Attribution-NonCommercial-ShareAlike 2.0 Generic license, image resized).

Bioethanol from sugarcane

In Brazil, where sugarcane is used, sugarcane stems are shredded and crushed to extract their juices. The cane juice can then be fermented, distilled, and passed through molecular sieves. The leftover solid organic material, called bagasse, is often burned to generate electricity. The leftover liquid is called vinasse and is simply a waste product.

An ethanol distillery at a combination sugar mill and ethanol plant, Piracicaba, Sao Paulo, Brazil. Photo by Mariordo/Mario Roberto Duran Ortiz (Wikimedia Commons, Creative Commons Attribution-ShareAlike 3.0 Unported license, image resized).

Sugarcane bagasse. Photo by Anna Frodesiak (Wikimedia Commons, CC0 1.0 universal/public domain dedication).

Use of bioethanol fuels

Most ethanol biofuel is used for transportation. In the United States, which is the top consumer of ethanol fuels, most gasoline sold to power passenger cars contains 10% ethanol and 90% gas from fossil fuels. This type of fuel is called E10.

Higher-ethanol fuels can be used in vehicles designed to take them. E85 (85% ethanol) fuel is also available in the U.S. for vehicles able to burn it. Brazil is the world's second largest consumer of ethanol fuels. Most cars in Brazil today are flex-fuel vehicles that can use gasoline from fossil fuels or ethanol.

Original caption: "An E85 (85% ethanol) gas pump at a fueling station in Inver Grove Heights, Minnesota." Photo by Tony Webster (flickr, Creative Commons Attribution 2.0 Generic license, image resized).

A fuel pump that can dispense both gas and ethanol, Sao Paulo, Brazil. Photo by Mariordo/Mario Roberto Duran Ortiz (Wikimedia Commons, Creative Commons Attribution-ShareAlike 3.0 Unported license, image resized).

Cellulosic ethanol

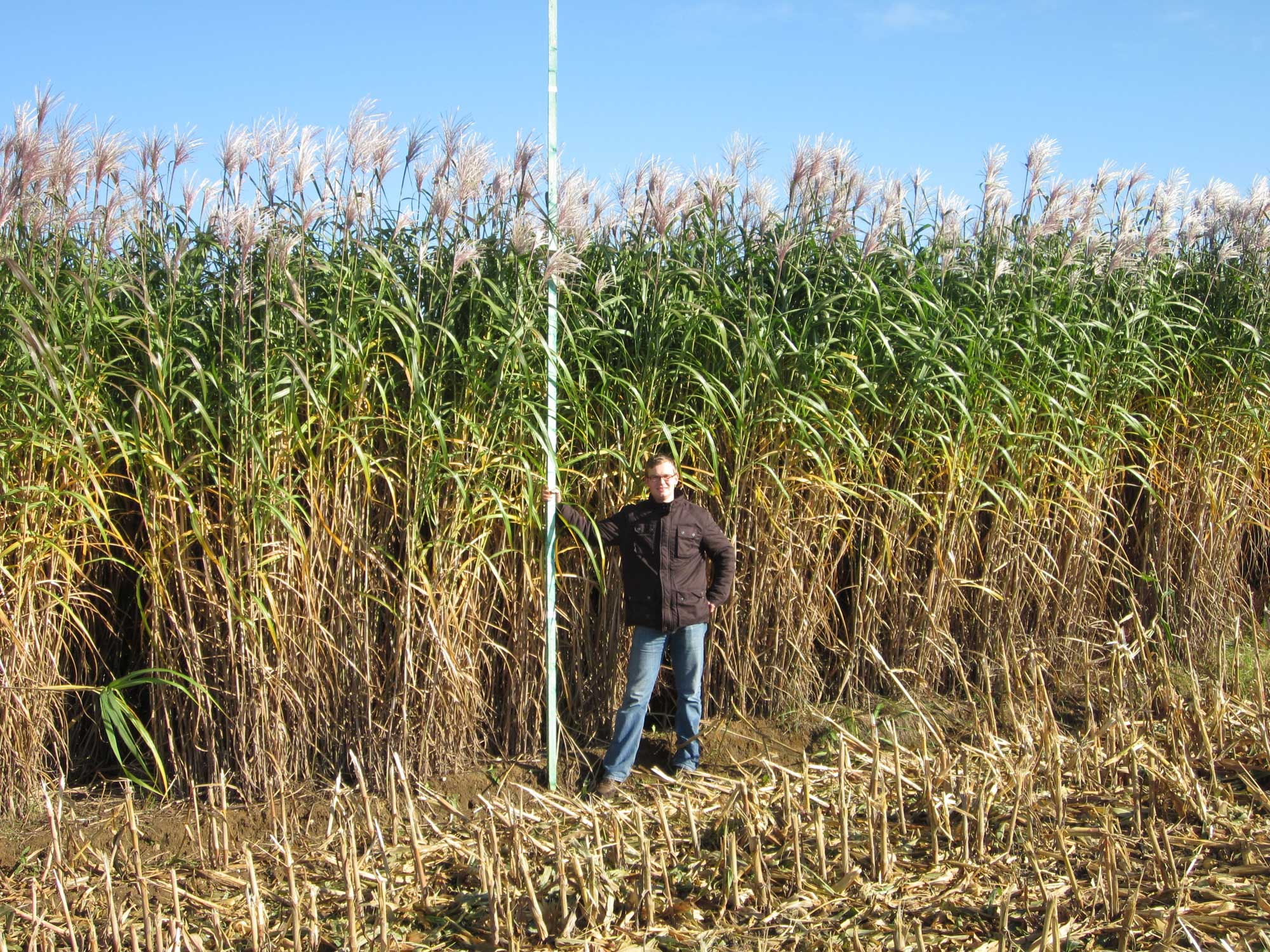

Cellulosic ethanol is a type of bioethanol made from trees or from the non-edible parts of crop plants. Cellulose is one of the components that make up the rigid material found in the cells walls of plants. In addition to maize stover (leaves and stalks) and sugarcane bagasse, some plant materials that are or could be used to make cellulosic ethanol include switchgrass (Panicum virgatum), miscanthus (various species of Miscanthus), sweet sorghum bagasse, and wood chips.

Switchgrass plots maintained by Cornell University in Ithaca, New York, 2016. Photo by Wikibiogas (Wikimedia Commons, Creative Commons Attribution-ShareAlike 4.0 International license, image resized).

Giant miscanthus (Miscanthus x giganteus), cultivated in Germany. Photo by Hamsterdancer (Wikimedia Commons, Creative Commons Attribution-ShareAlike 3.0 Unported license, image resized).

Although cellulosic ethanol production has the advantage of using parts of the plant that are not usually used for food and, therefore, often wasted, cellulosic ethanol requires a greater amount of processing to make. Like starch, cellulose must be broken down into sugars that yeast can convert into ethanol. Cellulose, however, is more difficult to break down than starch, requiring extra steps.

To date, production of cellulosic bioethanol is a small fraction of that produced from maize grain and sugarcane juice. Problems plaguing commercialization of cellulosic ethanol include economic hurdles (transporting the material is relatively expensive), storage problems (the material is flammable), and difficulties in processing.

Maize stover stored near wind turbines at an cellulosic ethanol facility in Nevada, Iowa, U.S.A., 2017. This facility later switched to making biomethane from maize stover. Photo by Dennis Schroeder/NREL (flickr, Creative Commons Attribution-NonCommercial-NoDerivs 2.0 Generic license).

Cellulosic ethanol is commercially produced from sugarcane bagasse in Brazil. Cellulosic ethanol production from sugarcane has the advantage that it can be combined with sugar milling or bioethanol production from sugarcane juice.

Bioethanol production from maize faces more hurdles because maize kernels are harvested using combines. Thus, maize stover has to be harvested and transported separately to produce biofuels, adding to the costs of making cellulosic ethanol from maize. Transportation costs are also a hurdle to producing ethanol from other crops, like switchgrass and miscanthus.

Maize stover harvest. Photo courtesy of Idaho National Laboratory (INL) Bioenergy Program (flickr, Creative Commons Attribution 2.0 Generic license, image cropped and resized).

Bailed switchgrass, 2008. Photo source: University of Tennessee (eXtension Farm Energy Community of Practice on flickr, Creative Commons Attribution-NonCommercial 2.0 Generic license, image resized).

Biodiesel

Biodiesel is a fuel made from animal fats, plant oils, or spent cooking oil. In order to produce biodiesel from plant sources, the plant oil is first refined and then treated with alcohol to convert the oil into two substances: biodiesel and glycerine. (Glycerine has a variety of industrial applications.)

Biodiesel is refined and may be mixed with fossils fuels before it is used. Biodiesel can be used as a fuel in diesel-burning vehicles like semi trucks and buses. It can also be mixed with heating oil from fossil fuel sources for use in home boilers and furnaces.

The main plant oil sources for making biodiesel in the U.S. are soybean (Glycine max, a legume), maize, and canola (Brassica napus, a plant in the mustard family). Genetically engineered sugarcane and sorghum are also being explored as sources of plant oil for biodiesel.

A fuel pump that dispenses biodiesel, 2011. Photo by the United Soybean Board (flickr, Creative Commons Attribution 2.0 Generic license, image cropped and resized).

Bio-oil extracted from genetically engineered sugarcane, 2017. Photo by Claire Benjamin/University of Illinois (flickr, Creative Commons Attribution 2.0 Generic license, image resized).

Biogas and biomethane

Biogas and biomethane are produced by breaking down organic matter using anaerobic digestion, a process in which bacteria decompose organic matter in an oxygen-free environment. The decomposition process produces digestate and biogas. Digestate contains solids and has several uses, including as a fertilizer.

Biogas is made up mostly of carbon dioxide (CO2) and methane (CH4), but also contains contaminants. It can be burned to generate electricity or heat. Alternatively, most of the carbon dioxide and contaminants can be removed from biogas to produce biomethane, which is used in the same ways as natural gas.

The organic matter used to make biogas and biomethane comes from various sources, like animal manure, distillers grains, sewage, and the inedible parts of crop plants, like leaves and stems. The remnants of grass grain crops like maize, rice (Oryza sativa), rye (Secale cereale), and wheat (Triticum) can be used for biogas production, as can fodder grasses like napier grass (Cenchrus purpureus) and sudangrass (Sorghum x drummondii), as well as sugarcane bagasse.

Biogas plant, Margarethen am Moos, Lower Austria, Austria. Photo by Robert Heilinger (Wikimedia Commons, Creative Commons Attribution-ShareAlike 3.0 Unported license, image cropped and resized).

Resources

Websites

Alternative Fuels Data Center (U.S. Department of Energy, Energy Efficiency & Renewable Energy): https://afdc.energy.gov/

An introduction to biogas and biomethane (IAE): https://www.iea.org/reports/outlook-for-biogas-and-biomethane-prospects-for-organic-growth/an-introduction-to-biogas-and-biomethane

Basic information about anaerobic digestion (United States Environmental Protection Agency): https://www.epa.gov/anaerobic-digestion/basic-information-about-anaerobic-digestion-ad

Biodiesel (Clean Fuels Alliance America): https://www.biodiesel.org/

Bioenergy Research Group (University of Hawaii): http://www2.hawaii.edu/~khanal/fungal/sugarcaneethanol.html

Biofuel basics (Bioenergy Technologies Office, Office of Energy Efficiency & Renewable Energy): https://www.energy.gov/eere/bioenergy/biofuel-basics

Biofuels explained (U.S. Energy Information Administration): https://www.eia.gov/energyexplained/biofuels/biodiesel-rd-other-use-supply.php

About biogas and biomethane (European Biogas Association): https://www.europeanbiogas.eu/about-biogas-and-biomethane/

Articles and reports

Great Lakes Bioenergy Research Center: Why is it so difficult to make cellulosic ethanol? PDF: https://energy.wisc.edu/sites/default/files/2017-05/Why%20is%20it%20so%20difficult%20to%20make%20cellulosic%20ethanol-.pdf

Kramer, D. 2022. Whatever happened to cellulosic ethanol? Physics Today 75(7): 22. https://doi.org/10.1063/PT.3.5036

Mosier, N. S., and K. Heleji. 2006. How fuel ethanol is made from corn. Purdue Extension, BioEnergy, ID-328, 4 pgs. PDF: https://www.extension.purdue.edu/extmedia/id/id-328.pdf

Wright, S. 2016. Why you can start heating with biodiesel today. Green Energy Consumers Alliance (blog post), December 17, 2016. https://blog.greenenergyconsumers.org/blog/start-biodiesel

Scientific articles

Lynd, L. R. 2017. The grand challenge of cellulosic biofuels. Nature Biotechnology 35: 912-915. https://doi.org/10.1038/nbt.3976

Rubin, E. M. 2008. Genomics of cellulosic biofuels. Nature 454: 841-845. https://doi.org/10.1038/nature07190